News

Let’s talk about whether it is feasible to ban rock wool insulation products | Vertical filament rock wool composite panels have broad market prospects

Release Time :

2021-12-09 14:34

Advantages and disadvantages of rock wool board insulation system

Compared with the organic insulation system in the energy-saving market, the biggest advantage of the rock wool board insulation system is the fire safety of the system. This is because rock wool, as an ideal Class A insulation material, has the advantages of non-combustibility, breathability, sound absorption, and high thermal stability. In addition, compared with Class A insulation materials such as foamed cement insulation boards, expanded perlite boards, and vitrified microbeads, rock wool insulation boards have smaller thermal conductivity and excellent thermal insulation properties. Under normal temperature conditions (around 25°C) The thermal conductivity of rock wool is usually between 0.036W/(m·K) and 0.040W/(m·K). But at the same time, there are also obvious shortcomings in the rock wool board insulation system, especially the rock wool board thin plaster insulation system, whether it is a rock wool board double-layer alkali-resistant fiberglass mesh structural system or a single-layer rock wool board alkali-resistant The fiberglass mesh structural system has exposed many problems in engineering applications in recent years. There have been many accidents of the rock wool thin plaster insulation system falling off. The main reasons are:

1. The tensile strength of the rock wool board itself is low, with a strength range of about 7.5kPa to 15kPa. Although the construction method of the thin plaster insulation system of the rock wool board is defined as mainly anchoring and supplemented by pasting, it may be due to the poor technical quality of the construction personnel. Low or due to factors such as limited construction site conditions, it is often difficult to meet the standard requirements for the number and strength of anchors, posing safety hazards;

2. As a relatively loose soft fibrous insulation material, rock wool board has high water absorption and hygroscopic properties. It has extremely strict requirements on the quality of construction and supporting materials, and the construction process is relatively complicated. If there are defects in the product quality and construction of supporting materials such as the plaster layer, facing layer, and mesh cloth of the system, micro-cracks appear, or the waterproofing measures at the connection between the system and other parts are improperly handled, external moisture will penetrate into the interior of the rock wool board and gradually accumulate, and then the Coupled with external influences such as wind pressure and weather resistance, it is easy to cause irreversible damage to the system;

3. Under the new situation of "double carbon" goal, building energy-saving standards will inevitably be further improved. To meet the new energy-saving standard requirements, conventional practice will inevitably require increasing the thickness of rock wool boards, so that the thin plaster insulation system of rock wool boards will The dead weight becomes greater, and the hidden dangers of project quality increase significantly.

The existence of the above problems, as well as the fact that the market is full of shoddy and shoddy rock wool boards and system supporting materials, have had a great negative impact on the use of rock wool boards in external insulation systems.

Structural design of vertical wire rock wool composite panels

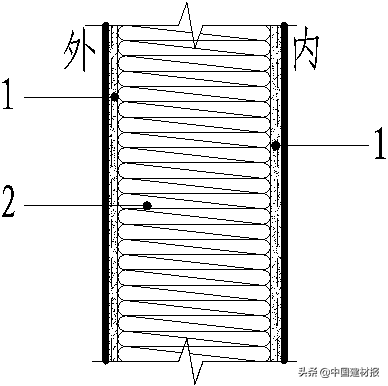

In order to solve the adverse effects of the low tensile strength of the rock wool board itself, the unprotected bare walls, and the high thermal conductivity required by high energy-saving design standards, a new type of vertical wire rock wool composite board was researched and designed. Vertical filament rock wool: The rock wool board is cut at a certain distance and turned over at 90 degrees. The main fiber layer direction is perpendicular to the surface. Compared with rock wool boards, the tensile strength of vertical filament rock wool has been greatly increased, reaching more than 0.10MPa, which is comparable to conventional EPS insulation boards. However, one of its disadvantages is that the width of vertical filament rock wool is currently only up to 200mm, which is more is 150mm; second, the thermal conductivity becomes larger, about 0.043W/(m·K) to 0.045W/(m·K). To this end, two types of vertical filament rock wool composite panels have been developed based on different energy-saving design standards. One uses vertical filament rock wool as the core material, and is composited on both sides with fiberglass mesh reinforced polymer mortar or special flexible cement-based sheets. The formed composite insulation board is marked as an A-type vertical wire rock wool composite board. Its basic structure is shown in Figure 1. It focuses on solving the problems of the small size of the vertical wire rock wool itself and the lack of necessary protective layers during construction in the bare board state.

Vertical wire rock wool composite board

The other is a composite insulation board made of vertical filament rock wool and organic insulation materials as the core material, with composite glass fiber mesh reinforced polymer mortar or special flexible cement-based sheets on both sides. It is marked as type AB. The basic structure of the vertical filament rock wool composite board is shown in Figure 2. In addition to the advantages of the A-type composite board, it is mainly based on the technical idea of inorganic/organic composite, giving full play to the fire protection advantages of inorganic materials and the thermal insulation advantages of organic materials, focusing on solving The thermal conductivity of vertical filament rock wool is too large and cannot be applied under high energy-saving design standards.

Experimental research has proven that rigid foam polyurethane (PU) is the primary choice for the organic insulation material of AB-type vertical filament rock wool composite panels. First, polyurethane has low thermal conductivity and excellent thermal insulation performance. Second, polyurethane can directly foam and penetrate into rock wool fibers. The combination is tight and the overall performance of the composite board is excellent. Thermal calculations show that the thermal insulation effect of the 70mm thick AB rock wool polyurethane composite board is better than that of the 110mm thick A type vertical wire rock wool composite board.

RELATED NEWS

2025-04-09

Unlocking the Benefits of High-Density Polyiso Roof Boards for Superior Insulation

High-density polyiso roof boards are a prominent choice in the construction and insulation industry, particularly when it comes to roofing applications. These boards are made from a rigid foam insulation material called polyisocyanurate, which is known for its excellent thermal performance. The high-density variant specifically refers to boards that are denser than standard options, offering numer

2025-04-08

Lightweight Polyiso Roof Board: Enhancing Comfort in Commercial Spaces

Lightweight Polyiso Roof Board: Enhancing Comfort in Commercial Spaces Table of Contents Introduction to Lightweight Polyiso Roof Boards What is Polyiso? Benefits of Lightweight Polyiso Roof Boards Energy Efficiency Enhanced Comfort Moisture Resistance and Durability Applications of Lightweight Polyiso Roof Boards Inst

2025-04-07

Understanding Rigid Closed-Cell Polyisocyanurate Insulation Boards: A Comprehensive Guide

Rigid closed-cell polyisocyanurate insulation boards are a highly efficient insulating material widely used in the building and construction industry. Known for their excellent thermal performance, these boards are composed of a closed-cell structure that prevents moisture absorption, making them ideal for a range of applications. Their unique properties provide significant advantages in energy ef

2025-04-06

Maximizing Energy Efficiency with Polyisocyanurate Rigid Foam Insulation Boards

Maximizing Energy Efficiency with Polyisocyanurate Rigid Foam Insulation Boards Understanding Polyisocyanurate Rigid Foam Insulation Polyisocyanurate, or polyiso, is a type of rigid foam insulation that is widely recognized for its outstanding thermal performance. With a high R-value per inch, polyiso insulation boards deliver superior energy efficiency, making them an ideal choice for both reside