News

What are the advantages of rock wool composite panel system?

Release Time :

2022-06-20 14:39

After nearly thirty years of development, the building energy-saving industry has formed a development trend of high standards, high requirements, and emphasis on quality. After several rounds of adjustments, the fire prevention policy has now established a policy dominated by Class A insulation materials. As a Class A fireproof insulation material, rock wool composite panels are widely used in the construction field.

Rock wool composite board is an improved product of traditional rock wool board. It uses vertical filament rock wool strips as the insulation core material. It is assembled through the arrangement of core materials. It uses double-sided coating of alkali-resistant mesh cloth and special flexible waterproof and crack-resistant mortar for resistance. It is cracked and waterproofed to produce a new type of vertical filament rock wool fireproof insulation board with thermal insulation and flame retardant functions, high tensile strength and low water absorption.

Advantages of rock wool composite board products

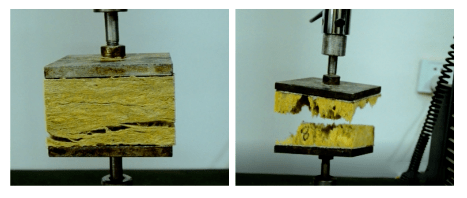

1. High tensile strength of the vertical board surface: special flexible polymer waterproof and crack-resistant mortar is used to prepare high-performance mortar for rock wool composite boards, which has high board surface strength and tensile strength.

Tensile strength test of mortar secondary molded rock wool composite panels

Tensile strength test of mortar secondary molded rock wool composite panels

2. Good hydrophobic performance: The polymer mortar used is mixed with silicone hydrophobic agent, which makes the rock wool composite board have a good hydrophobic effect.

The picture on the left is before spraying water. The picture on the right is after spraying water.

Surface water effect

Hydrophobicity test of mortar secondary molding rock wool composite board

3. Class A fireproof material: has good thermal insulation performance and significant sound absorption and noise reduction effect;

4. High safety: The rock wool composite board system adopts the "pasting + anchoring" fixing method, with bonding as the main method and anchoring as the supplement. Any anchoring must not be at the expense of bonding strength. Auxiliary anchors provide stabilization until the adhesive finally sets and serve as a temporary connection to prevent disengagement. After the adhesive solidifies, various anchors become safety reserves for fixing the insulation board. Even under the most unfavorable conditions (the adhesive completely falls off), it can ensure that the board will not fall off, ensuring the safety and reliability of the system;

5. The rock wool composite board has good flatness, high body strength, and good impact resistance: the vertical filament rock wool composite mortar reinforced mesh cloth has high strength. When applying mortar during construction and pasting the insulation board, it will not be deformed due to the weight of the mortar. , to ensure the convenience of construction, there is no need to cut and level the base layer, the size of the board makes the operation process easy to construct, and prevents the mortar from virtual sticking. At the same time, because the rock wool composite board is processed and produced using a high-precision fully automatic mechanized assembly line to ensure the flatness of the board surface, it ensures that the yin and yang angles behind the wall of the rock wool composite board are straight and square and the flatness of the wall surface is ensured;

6. Design your own scraper: Use the scraper to accurately control the thickness of the mortar to meet the needs of different thicknesses;

7. Stable quality: Use mechanized assembly line operations to reduce manual operations and ensure stable output of products.

RELATED NEWS

2025-04-09

Unlocking the Benefits of High-Density Polyiso Roof Boards for Superior Insulation

High-density polyiso roof boards are a prominent choice in the construction and insulation industry, particularly when it comes to roofing applications. These boards are made from a rigid foam insulation material called polyisocyanurate, which is known for its excellent thermal performance. The high-density variant specifically refers to boards that are denser than standard options, offering numer

2025-04-08

Lightweight Polyiso Roof Board: Enhancing Comfort in Commercial Spaces

Lightweight Polyiso Roof Board: Enhancing Comfort in Commercial Spaces Table of Contents Introduction to Lightweight Polyiso Roof Boards What is Polyiso? Benefits of Lightweight Polyiso Roof Boards Energy Efficiency Enhanced Comfort Moisture Resistance and Durability Applications of Lightweight Polyiso Roof Boards Inst

2025-04-07

Understanding Rigid Closed-Cell Polyisocyanurate Insulation Boards: A Comprehensive Guide

Rigid closed-cell polyisocyanurate insulation boards are a highly efficient insulating material widely used in the building and construction industry. Known for their excellent thermal performance, these boards are composed of a closed-cell structure that prevents moisture absorption, making them ideal for a range of applications. Their unique properties provide significant advantages in energy ef

2025-04-06

Maximizing Energy Efficiency with Polyisocyanurate Rigid Foam Insulation Boards

Maximizing Energy Efficiency with Polyisocyanurate Rigid Foam Insulation Boards Understanding Polyisocyanurate Rigid Foam Insulation Polyisocyanurate, or polyiso, is a type of rigid foam insulation that is widely recognized for its outstanding thermal performance. With a high R-value per inch, polyiso insulation boards deliver superior energy efficiency, making them an ideal choice for both reside