Product

PRODUCT CENTER

CONTACT US

No. 789, Xinglong Road, Wuyi Industrial Park, Nanqiao District, Chuzhou City, Anhui Province, China

Mobile

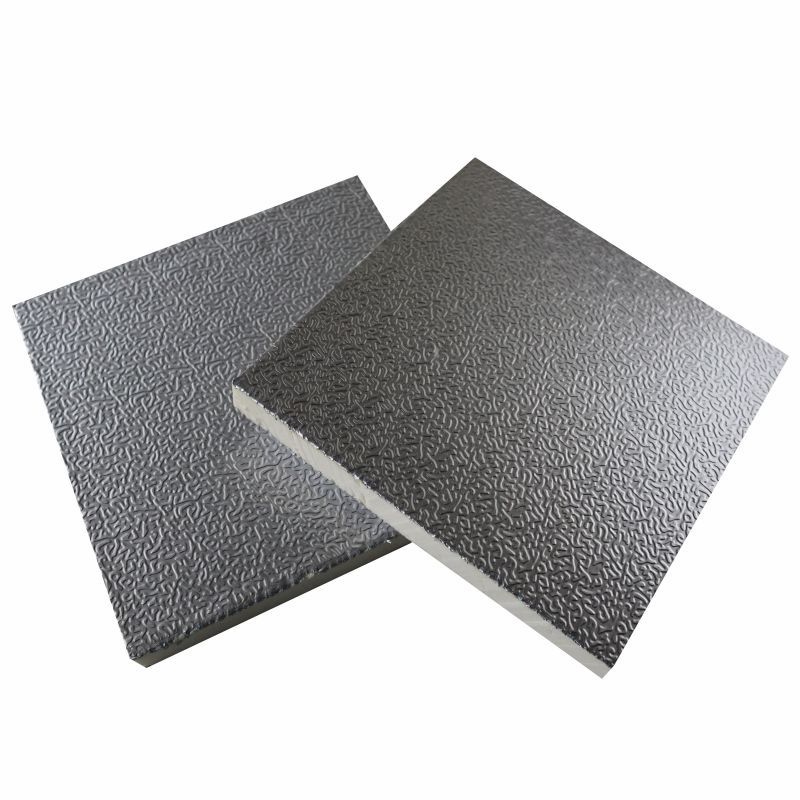

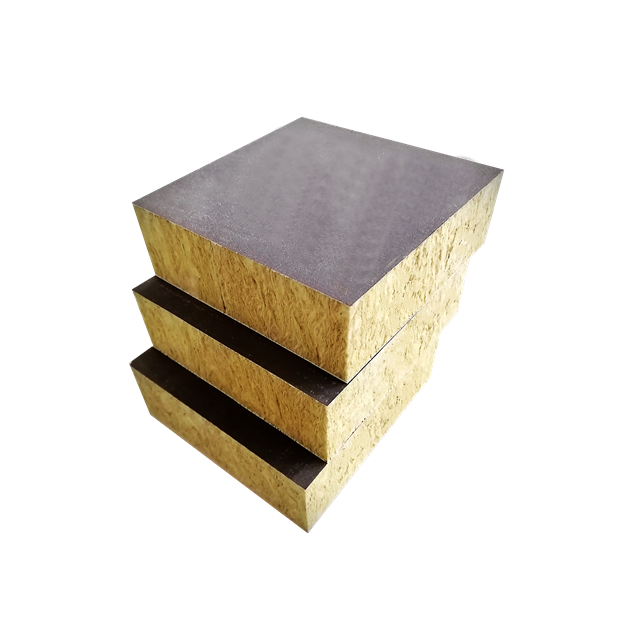

Rock wool board

Category :

Keywords :

Rock wool board

hiddenValue

PRODUCT DETAILS

Technical Data

| Product name | Rock wool Composite Insulation Boards | |

Finish | Material | Aluminum Foil Facings or Fiber Glass Papers (Mortar Papers) |

| Thickness | ≤0.8 mm | |

| Tensile Bond Strength | 0.12 MPa | |

| Colors | Customized available | |

Foam Core | Material | Basalt fiber |

| Density | 124 kg/m³ | |

| Thermal Conductivity | 0.043 W/m·K | |

| Dimensional Stability | ≤1.0 %(Length/width/Thickness) | |

| Color | yellow | |

| Water Absorption | ≤1kg/m²(24h/48h) | |

| Acidity coefficient | ≥1.6 | |

Uniform temperature burning performance (75□,0.5h) | linear shrinkage:5% Mass loss:4% | |

Insulation Board | Dimensions | Standard:1200x600 mm Customized:Length no limited,Width 1200 mm maximum |

| Thickness | 20-120mm | |

| Dimensional Stability | ≤1.0%(Length/width/Thickness) | |

| Compressive strength | ≥40 KPa | |

| Tensile Strength Perpendicular to Panel Direction |

≥100 KPa | |

| Closed porosity | ≥98% | |

| Hydrophobic rate | 99.2% | |

| Fire Rating | A1 | |

| Certification | ISO9 001 ,ISO14001 and ISO45001(OHSAS18001), Carbon Labelling' | |

| Applications | Roofs |Walls |Floors |Ceilings |HVAC System | |

WHAT IS ROCK WOOL?

Using selected basalt as the main raw material,the rock is melted at high temperature (greater than 1450°C).After the inorganic fiber is made by high-speed centrifugal equipment,a special binder and dust-proof oil are added,and then the felt is laid with a roller-collecting swing belt.,and use special equipment to change the fiber arrangement to arrange the rock wool fibers into a three-dimensional chaotic structure,and finally use solidification and shaping equipment to make a new lightweight insulation material.

Shipment Rock wool Composite Boards

Insulation | R-Value | R-ValueIn | Boards per | m2 | BoardsPer | m2 | Price | Lead | Payment |

| Standard(I):1200X600 mm | |||||||||

| 20 | 0.50 | 2.84 | 25 | 18 | 4750 | 3420 | Fob Shanghai | 25days | 100%T/T in advance |

| 30 | 0.75 | 4.26 | 17 | 12.24 | 3230 | 2325.6 | Fob Shanghai | 25days | 100%T/T in advance |

| 40 | 1.00 | 5.68 | 12 | 8.64 | 2280 | 1641.6 | Fob Shanghai | 25days | 100%T/T in advance |

| 50 | 1.25 | 7.10 | 10 | 7.2 | 1900 | 13680 | Fob Shanghai | 25days | 100%T/T in advance |

| 60 | 1.50 | 8.52 | 8 | 5.76 | 1520 | 1094.4 | Fob Shanghai | 25days | 100%T/T in advance |

| 70 | 1.75 | 9.94 | 7 | 5.04 | 1330 | 957.6 | Fob Shanghai | 25days | 100%T/T in advance |

| 80 | 2.00 | 11.36 | 6 | 4.32 | 1140 | 820.8 | Fob Shanghai | 25days | 100%T/T in advance |

| 90 | 2.25 | 12.78 | 5 | 3.60 | 950 | 684 | Fob Shanghai | 25days | 100%T/T in advance |

| 100 | 2.50 | 14.20 | 5 | 3.60 | 950 | 684 | Fob Shanghai | 25days | 100%T/T in advance |

| 110 | 2.75 | 15.62 | 4 | 2.88 | 760 | 547.2 | Fob Shanghai | 25days | 100%T/T in advance |

| 120 | 3.00 | 17.03 | 4 | 2.88 | 760 | 547.2 | Fob Shanghai | 25days | 100%T/T in advance |

Related Products

Online Message